Resource efficiency

Environment management system & procedures

Adhering to best practices and international standards, we certify our integrated management system to ensure operational excellence, enhance sustainability performance, and maintain compliance with global regulatory requirements. As of 2024, eight out of 12 of ACEN’s Philippine operating plants under our control have garnered the coveted Integrated Management System (IMS) certification on Environmental Management System (EMS) ISO 14001:2015, Quality Management System (QMS) ISO 9001:2015 and Occupational Health and Safety Management System (OHSMS) ISO 45001:2018.

This certification provides a framework to help organizations identify, manage, monitor and improve their environmental performance in a systematic manner, as verified by DQS Certification Philippines, Inc. It also enables us to have more efficient and streamlined processes, enhance compliance, improve risk management, increase stakeholder confidence, have more sustainable practices and induce continuous improvement. As we grow our renewables portfolio, we intend to have all plants certified under IMS to reinforce our dedication to sustainability and ensure continued operational excellence. Part of our plant operations’ quality management procedures is to ensure plant employees receive proper training on the implementation of the ESMS as it is subject to external compliance audits. Additionally, regular environmental impact audits are conducted annually across all our operational sites that are ISO-certified, which take into consideration the management of waste, water and energy.

Waste management

Our plants implement waste management initiatives customized to their operations, all of which are aligned with country regulatory policies and international standards. In developing environmental and social management plans, we integrate efforts to minimize, reduce and reuse waste throughout the life cycle of our projects. We also ensure that appropriate onsite materials recovery facilities are present on each project site and waste management procedures per country of operation are implemented. Additionally, we implement waste segregation systems in our plants that incorporate reduction initiatives, minimizing the use of polyethylene terephthalate (PET) bottles and other single-use plastics.

In the Philippines, we are the first renewable energy company to implement an integrated circular approach in our solar developments. With a strong focus on sustainability,

we continue to engage multiple stakeholders across various phases of our value chain from the plant’s development stage to its commercial operations. This helps us reframe workstreams on plant waste management and integrate our circularity framework into Engineering, Procurement and Construction (EPC) contracts.

Scaling up our

circularity approach

We are advancing our circularity efforts by collaborating with more sustainable waste management partners like Integrated Waste Management (IWM), a subsidiary of AC Logistics. This partnership has enabled us to work with Sentinel Upcycling Technologies and Zolo Philippines Corporation to upcycle our plastic waste and manage our electronic waste (e-waste) effectively.

Through these collaborations, Sentinel has collected approximately 8.9 tons of plastic waste from Palauig Solar (Phase 2), which is now being used to produce upcycled products such as pallets, crates and furniture.

Plastics diverted from landfill

8,900 kg

At our corporate office, through ACEN Shared Services (ACES), we have turned over our e-waste to IWM. Through its partnership with Zolo, IWM ensured that the collected e-waste will be repaired, reused, refurbished, recycled or resold. By turning over a total of 110 used computers, laptops, monitors, keyboards and printers, we diverted 220 kilograms of e-waste from landfills, avoiding approximately 27.8 tons of carbon emissions.

Across our Philippine sites, we implement paperless initiatives by using cloud-based or digital forms to minimize paper waste. In Palauig Solar, organic fertilizers from vermicomposting cow manure and biodegradable waste helped reduce waste disposal and lowered methane emissions associated with waste breakdown. We also continue to increase awareness and knowledge on waste management, with employees from Alaminos Solar celebrating World Environment Day by attending learning sessions that discussed waste recycling and plastic pollution.

We ramped up our circularity efforts with an e-waste management initiative with IWM to transform our e-waste into recycled products.

Across our international sites, our Vietnam and U.S. plants are implementing repair and refurbishment practices as part of our maintenance work. These efforts help reduce waste and lower procurement costs.

In Australia, New England Solar and Stubbo Solar are leading the way in circularity. Beyond the reduce-and-reuse approach for operational compliance, we promote sustainable value chains by engaging contractors and favoring suppliers who limit plastic usage and ensure responsible transportation of packaging to recycling facilities. EPC contractors are required to implement a waste management plan, procure materials that have recycled components and are requested to purchase locally where possible to reduce transport emissions. In both plants, an evaporation septic system has been established in their respective operations building which includes the primary waste treatment and a series of trenches and pipes to allow natural absorption of waste.

Our project team in New England Solar provides damaged PV modules to a local recycling facility. In addition, all steel, timber pallets, cable reels and other waste timber from the site have been recycled.

Across our India and Vietnam plants, hazardous waste is managed through recycling methods and buyback procurement for battery waste. Damaged modules, depending on the extent, are either repaired on site or recycled to minimize disposal.

In 2024, our total waste generation declined by 26 percent compared to previous year as a result of lower fuel consumed by our thermal plants. For non-hazardous waste, 65% of waste generated from our projects were diverted from the landfill, reflecting our efforts on circularity.

Waste generation (in kg)

End-of-life management

Our commitment to responsibly managing waste entails ensuring that we adhere to best-in-class standards on end-of-life management. EPC contractors for projects that are under development are required to adhere to our ESG policy as well as to the Environmental and Social Management System (ESMS). We also select and monitor EPC contractors that comply with applicable standards provided by International Electrotechnical Commission (IEC) standards and ISO standards.

Our EPC contractors implement appropriate waste management practices for the disposal of PV panels, including recommended treatment, storage and disposal facilities within the operational areas, as well as cost estimates for each waste management step. During the operational phase, we also include end-of-life plans that adhere to national regulations and are tailor-made to address the structural specifications, stakeholder concerns and environmental conditions of the project site.

In 2024, ACEN Australia joined the Circular PV Alliance (CPVA) as an industry member. CPVA is a not-for-profit industry body focused on transitioning solar energy to a circular economy through innovation, high standards and a sustainable approach to the renewable energy transition.

ACEN Australia is also partnering with Yurruga, a start-up Indigenous business based in Dubbo. This partnership aims to explore solutions for the responsible recovery of materials from solar PV panels at our solar energy facilities. We are working towards establishing a commercial agreement on circularity services which include receiving, testing (for reuse), recycling and resource recovery of used or decommissioned PV panels from Stubbo Solar. This collaboration reflects a shared commitment to regional and Indigenous business innovation, supporting Australia’s transition to a clean energy future.

Lastly, we continuously explore strategies to extend the useful life of existing wind project. In the U.S.A., for example, we are extending the useful life of existing wind project, including the 136 MW Stockyard Wind in Texas, through preventative maintenance and repowering.

In the U.S., through our joint venture with PivotGen and UPC Solar & Wind Investments, we are extending the useful life of existing wind farms through preventative maintenance and repowering.

Water management

We pursue water stewardship in our projects and offices by transitioning from freshwater to alternative sources, implementing water efficiency practices and discharging used water responsibility. We also adhere to local and national water management regulations for both projects under development and in operation.

Our strategy of developing solar and wind projects, which are generally low water-intensive, enables us to minimize exposure from risks associated with water scarcity. Despite having low risk, we maintain our

efforts to promote water efficiency.

In the Philippines, we promote water conservation by placing signages to remind employees of responsible water use. In Palauig Solar, we efficiently use a rainwater harvesting system to utilize natural precipitation for facility needs such as PV module cleaning. MonteSol and SaCaSol are using automated cleaning machines to reduce water usage. NLR and NorthWind have installed water meters across their facility to monitor water usage and establish water reduction targets.

In New England Solar and Stubbo Solar, rainwater tanks are attached to operations warehouses. The captured rainwater will be utilized for all water requirements in the office and ongoing landscape management. The operational buildings are equipped with water-efficient fixtures for taps and toilets to minimize overall water usage

During construction, all water required for dust suppression was sourced from non-potable sources such as the use of onsite dams. In our India sites, we use pressure nozzles in module cleaning tractors and properly designed water drainage systems for efficient rainwater discharge.

We also ensure that wastewater coming from our sites is treated in compliance with national regulatory standards. We also regularly test for harmful substances to help preserve the marine ecosystem. For example, in Mui Ne Wind in Vietnam, all wastewater generated on-site is treated through a three-compartment septic tank system, preventing discharge into the environment. Once the tank reaches capacity, a contracted, licensed company is responsible for the collection, transport and proper treatment of the wastewater, ensuring it meets all environmental requirements.

In 2024, our water use increased slightly by 8 percent due to projects that began operations during the year. Meanwhile, water intensity which is measured in terms of cubic meters of water withdrawn per MWh of energy generated decreased by 30 percent, from 0.043 to 0.030. This exceeds our annual target of 5 percent reduction in total water intensity year-on-year.

Water use (in cubic meters)

Energy management

As part of our resource efficiency efforts, we implement initiatives to reduce energy consumption and comply with regulatory requirements on energy management.

Across our sites, we use various strategies to conserve energy, including retrofitting or upgrading existing systems with newer, more efficient technologies, optimizing operations and maintenance to minimize energy use and promoting behavioral adjustments.

Electricity used from renewable sources

20.9 GWh

In Palauig Solar, we installed solar panels as roofing for the control building’s parking area to reduce energy consumption. The project also tracks energy export and import and vehicle trips to optimize transportation and minimize facility light usage. To ensure optimal performance and reduce energy wastage, regular cleaning and maintenance of air-conditioning units’ (ACU) air filters are conducted. Similarly, our SanMar Solar implements route and fuel optimization planning to reduce fuel use.

Several behavioral energy-saving measures are carried out across our sites, including turning off machinery and equipment when not in use.

We also engage energy auditors to identify efficiency initiatives. For example, in NLR and NorthWind, we set office temperatures to 24°C as recommended by auditors. This has led to a 6 percent reduction in energy consumption for each degree Celsius.

In Palauig Solar, we optimize energy efficiency by installing solar panel roofing over the control building’s parking area, reducing energy consumption while maximizing clean energy use.

Our facilities in Mui Ne Wind are powered by our own turbines whenever they’re operating, harnessing clean energy on-site.

In Australia, New England Solar and Stubbo Solar’s electricity requirements for the operation of the plants are mitigated through the Large Scale Generation Certificates (LGCs) process. In New England Solar, a 50 KW solar panel array was installed on the operations warehouse to minimize emissions. In Stubbo solar, two electric vehicle charging points have been included within the design of its car park, promoting the use of electric vehicles.

In Vietnam, Lac Hoa and Hoa Dong Wind’s infrastructure lighting is energized through solar power. In Ninh Thuan Solar, a practice of adjusting a timer for the perimeter lighting within the plant is being implemented, ensuring the optimization of lighting when appropriate given the change of sunrise and sunset in each quarter of the year. In Mui Ne Wind, electricity used to power facilities comes from own generation when the turbines are operating, minimizing electricity purchased from the grid. Lastly, in our Super (Solar NT) sites, a car service has been provided to encourage carpooling, reduce individual emissions and support employee safety.

In 2024, our fuel consumption decreased signifiantly by 34 percent given the lower dispatch from our thermal plants, while purchased electricity increased signifiantly, driven by Alaminos Energy Storage’s first full year of operations.

We also started reporting self-generated and consumed electricity which amounted to 24.7 GWh. Electricity from our own generation across our renewable plants reached 20.9 GWh, reducing the need to purchase electricity from the grid and avoiding ~14,800 tCO2e of scope 2 emissions.

Energy consumption (in GWh)

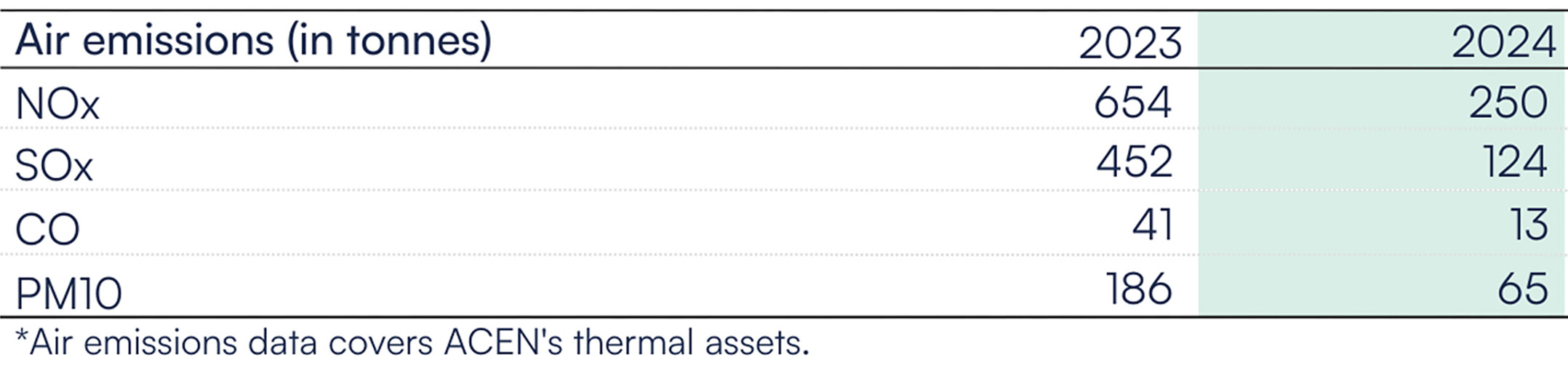

Air emissions

ACEN monitors its air emissions from its thermal assets.

There was a 67% decrease year-on-year on air emissions as a result of lower dispatch from these plants.